3D printing is becoming increasingly popular and is being used in a wide range of applications. The applications of 3D printers extend from the private sector to teaching, research and development, and industrial production.

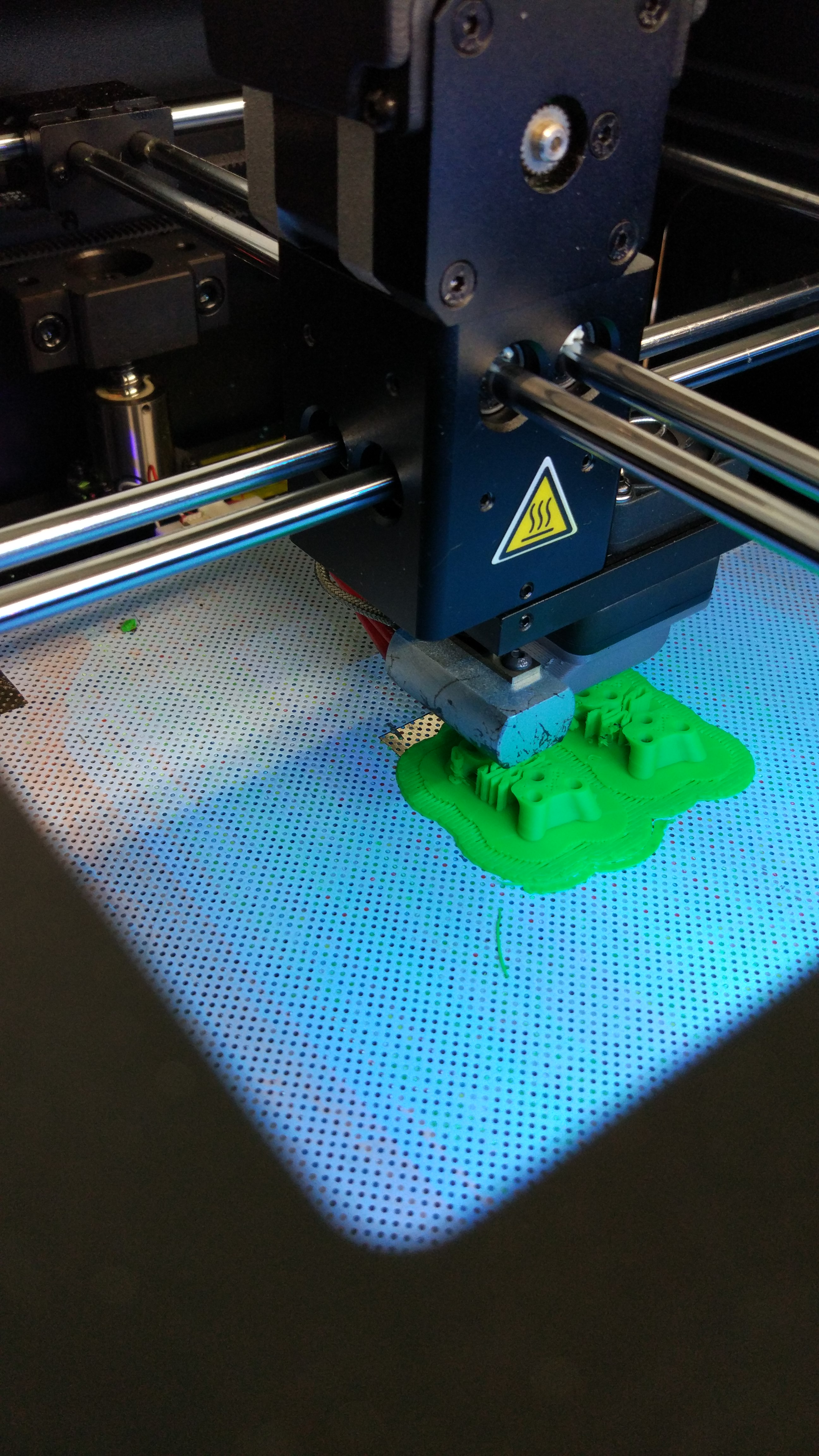

Among the 3D printing processes, fused deposition modeling (FDM) is one of the most widely used techniques. The filaments often consist of thermoplastics such as polylactic acids (PLA) and acrylonitrile-butadiene-styrene copolymers (ABS). These plastics are melted and applied to a work surface by an extruder under pressure. The temperatures during the melting process are usually between 180 °C and 270 °C. Ultrafine particles (UFPs) and volatile organic compounds (VOCs) can be released during this process.

As a result, the operation of a 3D printer can also affect indoor air quality. Under certain circumstances, the emissions can be harmful to health.